The adjustment range of the Barmag Spinning Machine Winder Parts Tensioning Block is usually determined by the type and specification of the yarn and the requirements of the production process. The adjustment range of the tension block is relatively wide and can adapt to different yarn requirements from fine yarn to coarse yarn. Due to its high orientation, FDY yarn can use a larger yarn guide angle during the winding process to increase the winding density; while industrial high-strength yarn requires a specially designed yarn guide angle to balance tension and wear resistance. Jiaxing Shengbang Mechanical Equipment Co., Ltd.'s multifunctional spinning test machine can conduct systematic tests on different yarn varieties and provide customers with the optimal yarn guide angle and tension block adjustment parameters.

In actual operation, accurate adjustment of the Barmag Spinning Machine Winder Parts Tensioning Block is a key step to ensure yarn quality. The following are some commonly used adjustment methods:

Mechanical adjustment:

Screw or spring adjustment: By adjusting mechanical components such as screws or springs on the tension block, the pressure of the tension block on the yarn can be changed, thereby adjusting the tension of the yarn. Our production department has a machining workshop with advanced CNC machine tools and other equipment, which can accurately process key components such as tension blocks to ensure the stability of their size and precision. During the adjustment process, professional torque wrenches and other tools are needed to ensure that the tightening force of the screws is consistent to avoid uneven force on the tension block due to uneven tightening force.

Yarn guide position adjustment: The position of the yarn guide will also affect the tension of the yarn. By adjusting the up and down, left and right positions of the yarn guide, the contact point and wrap angle of the yarn on the tension block can be changed to adjust the tension.

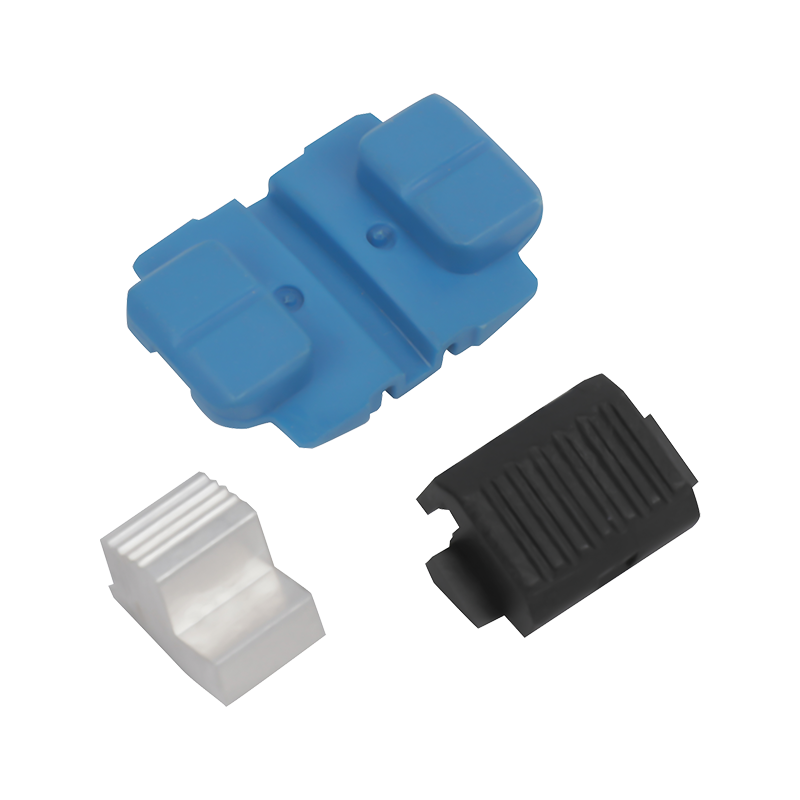

Tension block shape adjustment: In some special cases, it may be necessary to modify the shape of the tension block to adapt to different yarn varieties or production processes. Shengbang Mechanical's R&D department can design and process the required tension block shape according to customer needs to ensure stable and uniform tension of the yarn.

Experience adjustment:

Trial and error adjustment: In long-term production practice, operators will accumulate certain experience. According to the type and specification of the yarn and the actual situation in the production process, the tension block can be gradually adjusted by trial and error to achieve the best tension control effect.

Data recording and analysis: During the adjustment process, the parameters and results of each adjustment should be recorded in detail for subsequent analysis and summary. The data recording and analysis tools we provide can help operators better understand the rules and characteristics of tension block adjustment and improve adjustment efficiency and accuracy.

During the precise adjustment process, the following points should be noted:

Before adjustment, the equipment should be fully inspected and maintained to ensure that all components are in good working condition. We provide comprehensive maintenance services, including regular maintenance, troubleshooting and parts replacement, to ensure the stable operation of the Barmag spinning machine winder. The adjustment process should be carried out step by step to avoid excessive one-time adjustment resulting in uncontrolled yarn tension. After adjustment, the tension of the yarn should be monitored and recorded in real time to detect and solve problems in a timely manner. Shengbang Mechanical has advanced testing equipment and laboratories, which can monitor and analyze parameters such as yarn tension and winding density in real time, providing customers with timely and accurate data support. With its rich experience in the field of filament production and mature systematic technology, the company has developed a revolutionary multi-functional spinning test machine that can easily produce single-component yarn, two-component yarn, multi-component yarn, POY, FDY, medium-strength yarn and filament. At the same time, the company also has a spinning laboratory for sample preparation, where customers can also conduct spinning tests.

简体中文

简体中文